In order to meet the diverse customization requirements of customers, Sui On Insulation provides various deep processing services such as composite, coating, stamping, cutting, etc. At the same time, Ruian Insulation has introduced internationally advanced production management systems, strictly implementing ISO9001, ISO14001, and IATF16949 management system standards, and is committed to delivering validated processing materials. At present, we have provided precise and efficient high-quality services to well-known domestic and foreign enterprises, and helped customers create maximum value.

Cold Stamping Forming

Hot Forming Processing

Ultrasonic Welding Processing

Cutting And Processing Services

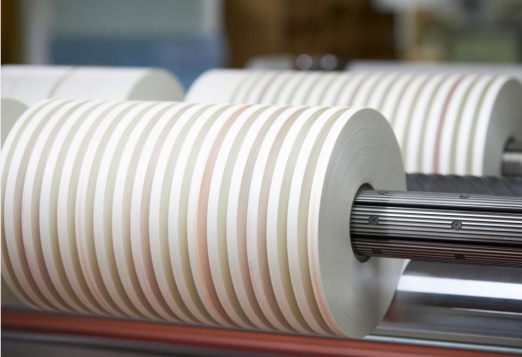

Composite&Glue Processing

Our equipment and processes can provide high-precision and high-efficiency composite coating processing services, meeting customers' strict requirements for quality and performance.